Including magnetizing equipment, magnetizer, magnetizing coil, chiller, magnetic flux meter (optional), magnetic detection software, Gaussmeter.

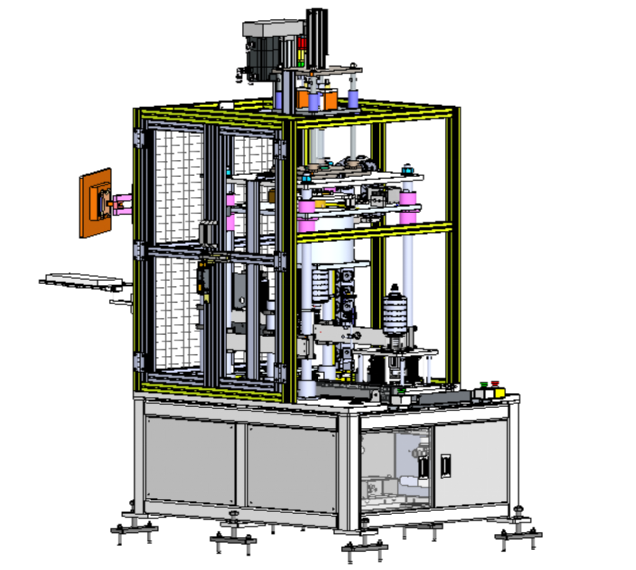

1. Wide compatibility range of rotor

2. Simple operation, high automation length, and anti misoperation capabilities

3. Easy to change models + Replacement car (optional)

4. Compatible with both manual loading and unloading and robot loading and unloading modes

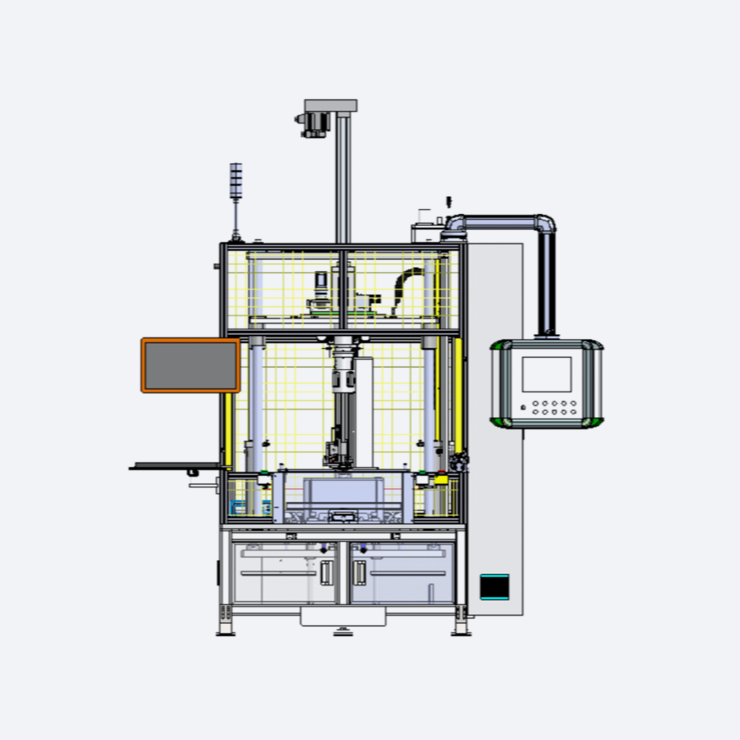

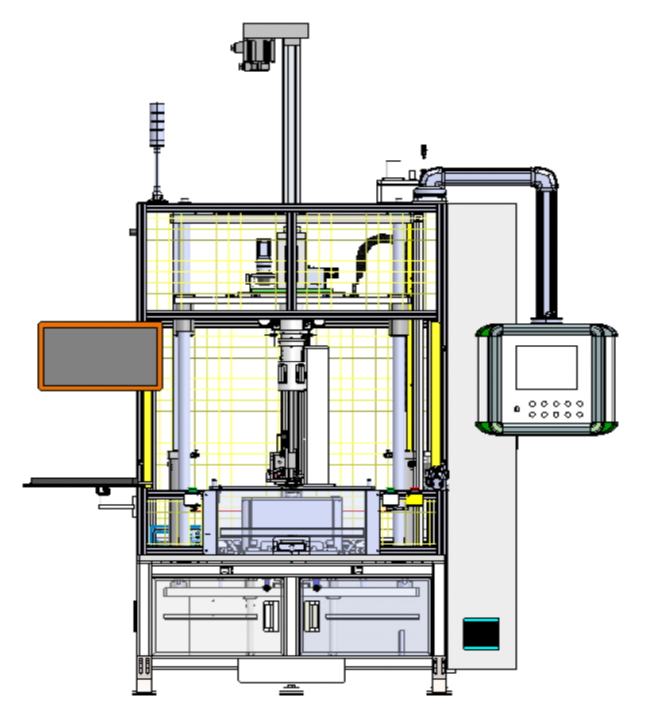

5. The magnetizing detection coil is fixed on the table

6. Communication with magnetizing power supply, real-time monitoring of equipment status

7. Can embed magnetic flux detection and magnetization + Integrated magnetic flux

Project | Technical Specifications | Remarks |

Input power | AC220V±5% 50/60Hz | |

Input current | < 20A | |

Rated power | < 5KW | |

Equipment noise | ≤ 75dB | Excluding instant magnetization |

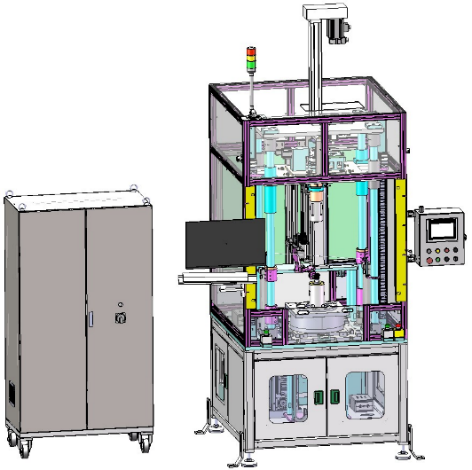

Device dimensions | Machine length, width, and height approximately: 1100 x1160 x 2350mm The length, width, and height of the electrical cabinet are approximately 900 x 500 x 1600mm | |

Equipment weight | < 1500kg | |

Changeover time | ≤ 30min | Tooling+Coil |

1 | Environmental temperature: 0 ℃~40 ℃ |

2 | Environmental humidity<80% (no condensation allowed) |

3 | Factory height (column top height): 3.5m |

4 | Ground load:>2 tons/m2 |

5 | Dimensions of the transportation door for factory equipment: width 1500 x height 2500mm |

6 | Gas source: pressure 0.4-0.6Mpa, flow rate 0.3m3/min |

7 | No dust, no oil fumes, no salt, no dripping water |

8 | Avoid direct sunlight exposure |

9 | No flammable or corrosive liquids or gases |

10 | No impact or high-frequency vibration |

11 | Location of use: Workshop open environment |